联络员:Lapin Vyacheslav Aleksandrovich

地址:624091, Russia, Sverdlovsk region, sity Verkhnyaya Pyshma, Uspensky avenue, h. 3, of. 605

电话:+7-34368-78-300

邮箱:university@tu-ugmk.com

Technical university of UMMC (UMMC TU) is the private engineering university in Russia, a modern model of partnership between business and education:

- Higher education programs;

- Applied scientific research;

- Design of technologies on a turnkey.

Scientific, research and design institute UMMC TU stands for:

- Unique laboratory equipment;

- Highly qualified specialists;

- Best practices in problem solution for real production;

- Pilot testing;

- Guaranteed quality result.

Areas of research:

- Development of energy and resource saving technologies for non-ferrous industry;

- Ore preparation and concentration;

- Creating powder materials, including additive technologies;

- Rare metals;

- Chemical analysis and material properties (instrumental procedures of analysis);

- Automation of technological processes;

- Geology and surveying;

- Design of industrial and civil facilities.

Development of energy and resource saving technologies for non-ferrous industry

- Improvement of pyrometallurgical processes and processing of complex sulphide concentrates and intermediate products;

- Enhancement of converting parameters;

- Dust collection and gas cleaning;

- Technologies of pressure hydrometallurgical processing;

- Complex purification of mine and waste technological waters;

- Development of new product mix;

- Application of industry-related raw materials and intermediate products.

Ore preparation and concentration

- Development of procedures for and improvement of flotation and gravity concentration regimes;

- Generation of reagents for flotation of complex ores and minerals;

- Development and production of mineral processing equipment of a modular type with increased efficiency and selectivity of the process;

- Increasing of efficiency of ore pretreatment.

Creating powder materials

- Analysis of the structure and properties of metallic powders for the subsequent production of items with specified properties;

- Development of production technology and production of powders (copper, zinc, silver);

- Development of new types of products manufactured using powder metallurgy technologies.

Rare metals

- Development of technologies for recovery of minor metals in ferrous and non-ferrous metallurgy;

- Development of technologies for obtaining high-purity minor metals;

- Recovery of minor metals from various types of process wastes.

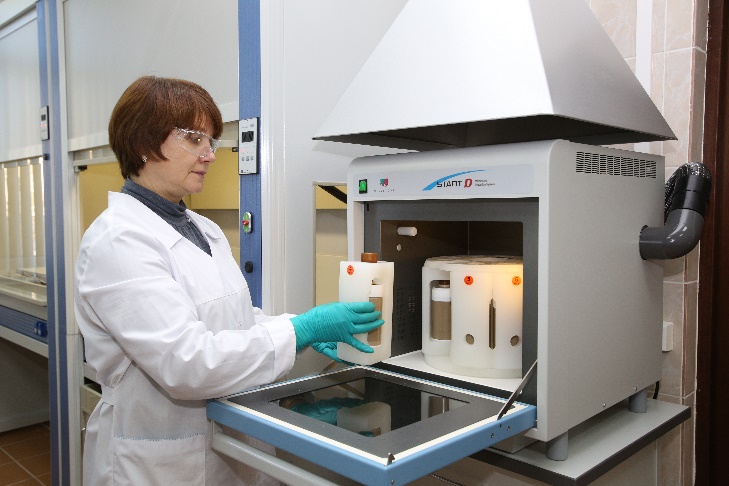

Instrumental procedures of analysis

- Qualitative and quantitative methods (X-ray phase analysis, rapid analysis, etc.);

- Integral material composition determination (grain size analysis, chemical analysis, phase analysis);

- Approved test methods;

- Wide scope of accreditation;

- Highly precise results within short time.

Automation of technological processes

Automated control systems:

- Development of hardware and software package for automation system;

- Development of methodology and applications and implementation of process control systems;

- Study of process automization systems and development of technical solutions for improvement of control system reliability and effectiveness.

Automated electric drives:

- Research of various operation modes for controllable DC and AC electric drives;

- Selection of an energy efficient electric drive on the basis of research and comparative evaluation of capacity of different types of electric drives in terms of introduction of energy efficient operation and control modes;

- Task modeling: commissioning, maintenance, troubleshooting of control systems based on frequency converters of various brands.

Geology and surveying

- Development and improvement of surveying techniques to ensure construction and

operation of engineering structures and facilities;

- Monitoring of engineering structures (building tilt and displacement of elements, foundation base settlement), high-rise structures and dams;

- Research and forecasting of geomechanics of the displacement of rocks and the Earth’s surface during mineral resources exploitation; estimation of the possible mining effect on the state of the earth’s surface;

- Development and improvement of methods for the establishing norms for and the determination and recording of losses and dilution of mineral resources, economic evaluation of damage from losses and dilution of mineral resources during field development;

- Surveillance and research of deposits’ quality to determine a cost-efficient mining method to be used;

- Mineralogical and technological evaluation of ferrous, nonferrous and precious metals ores.