In light of the development plan of the 13th Five-Year Plan of China and Beijing Municipality, Key Laboratory of Environmental Noise and Vibration of Institute of Urban Safety and Environmental Science, Beijing Academy of Science and Technology closely focuses on the goal of harmonious and livable city and green building with the aim to enhance residents' living safety and comfort. In order to address the issue of noise pollution, the Laboratory has launched in-depth research on key technologies of acoustic functional materials and structural design with the support of the National Natural Science Foundation of China, Beijing Natural Science Foundation and Beijing Academy of Science and Technology’s Innovative Team Project for many years. The programs of the research cover the fields of micro-perforated panel sound absorption structure, microporous soft film ceiling space sound absorber, nonlinear magnetic sound absorption structure, new sound insulation structure, ultra-thin textile materials as well as other acoustic functional materials, which are specifically listed as below:

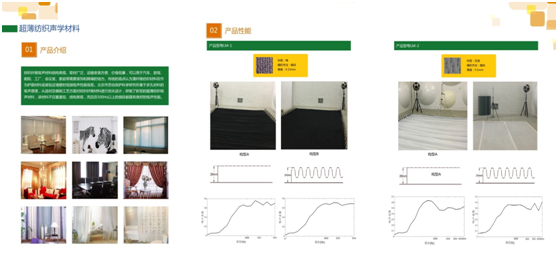

(1) Sound absorption structure of micro-perforated panel

In application, though the sound absorption property of micro-perforated panel has reached or even surpassed the requirements in practical use, staggered sound absorption structure of micro-perforated panel cannot be used due to the fact that the micro-perforated panel is too thin and too weak in strength. To address this issue, a staggered perforated panel sound absorption structure with double-layer (or multi-layer) is designed; this structure makes the micropore easy to process and controllable in size. With this design, the coefficient and bandwidth of sound absorption can be increased, which will effectively raise the level of noise reduction, alleviate noise pollution and improve the quality of the surrounding acoustic environment.

The manufacturing technology of heat-shrinkable micro-perforated panel is developed to address the issue that it is difficult for traditional machining to achieve ultra-micropore while laser drilling technology is relatively expensive. Based on the characteristic of heat shrinkage of heat-shrinkable sheets, larger holes are first made on the sheet with traditional process, and then ultra-micropores are made through heat treatment. With low cost of material, satisfactory structural strength in engineering application, and graceful patterns (if necessary), the technology can be applied in places that require decoration and noise reduction.

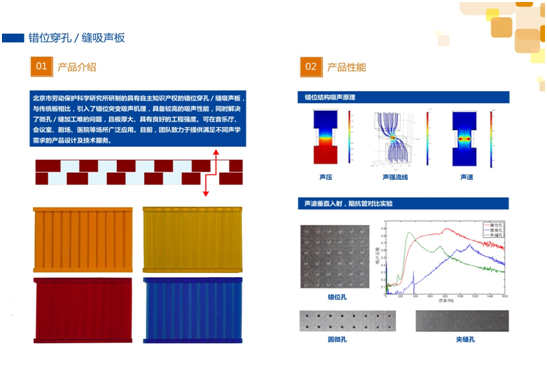

(2) Microporous soft film ceiling space sound absorber

With soft film ceiling as the base material, the research organization studies the design theory of sound absorber of microporous soft film ceiling, explores a low-cost and large-scale microporous molding process of soft film ceiling, and develops a microporous soft film ceiling material with independent intellectual property rights, which is provided with both decorative and acoustic functions. On this basis, the researcher designs single-layer microporous soft film ceiling sound absorption structure, double-layer microporous soft film ceiling sound absorption structure and microporous soft film space sound absorber with excellent sound absorption performance, builds the corresponding theoretical calculation model, comes up with the optimization design method, and promotes its application. The project achievement takes into account both decorative and acoustic functions, and tremendously fulfills the public's dual requirements for decoration design of public buildings and indoor acoustic environment.

(3) New nonlinear sound absorption structure

In order to solve the problem that it is difficult to design a light and thin sound-absorbing structure because the back cavity depth of low-frequency resonance sound-absorbing structure is large and the frequency band is narrow, taking thin-film sound-absorbing structure as the research object, this study designs thin, low-frequency and wide-band nonlinear thin-film sound-absorbing metamaterials through the action of magnetic field nonlinearity and local resonance mechanism of periodic sound-absorbing structure, muffler and sound barrier in aviation, industry and transportation.

(4) New sound insulation structure

New ventilation and sound insulation structure: in practical application, to achieve effect of ideal sound insulation, sound insulation materials are often required to be thick with enough density. However, due to the limitations of space and cost, the sound insulation effect of materials often falls short of people's expectations. Besides, there are strict requirements on the weight, size and ventilation of materials in some special places. In view of this, a new type of ventilation and sound insulation structure is developed and designed, which not only conforms to the sound insulation performance of the structure, but also carries the functions of ventilation and heat dissipation.

Nonlinear intelligent sound insulation metamaterial: in view of all sorts of environmental noise, based on the original research on sound absorption and insulation mechanism and structural optimization design of magneto-acoustic metamaterials with reference to active and passive control theories, the design and development of intelligent nonlinear sound insulation metamaterials are completed with magnetic nonlinear characteristics and artificial periodic structure, realizing the active and passive control of sound areas. Such materials are characterized with flexible arrangement and multi-frequency adjustable active and passive sound insulation, which can conform to all types of requirements of different specific acoustic environments and realize flexible management, protection and regulation of acoustic environments.

(5)Ultrathin textile materials

Beautiful in structure, extensive in material source, convenient in transportation and installation and inexpensive in price, textile fiber sound absorbing materials can be used in cars, hotels, theaters, conference rooms, families and other places that require decoration and noise reduction. According to the traditional view, the sound absorption performance of thin fiber materials is rather poor. A new type of ultra-thin textile sound absorption materials is developed based on the sound absorption principle of porous materials, with optimization in respect of material selection and weaving technology. Such materials are not only light in weight and beautiful in structure, but demonstrate excellent sound absorption performance in the frequency band above 500Hz.

Intellectual Property Rights and Awards:

The project has acquired 27 authorized patents and 3 invention patents of substantive examination, and won the Most Practical Value Award of China Innovation Challenge (Beijing).

Ultra-thin Textile Acoustic Materials

Dislocation Perforated/Slotted Acoustic Panel Absorber

MicroporousSoft Film Ceiling Sound-Absorbing Materials

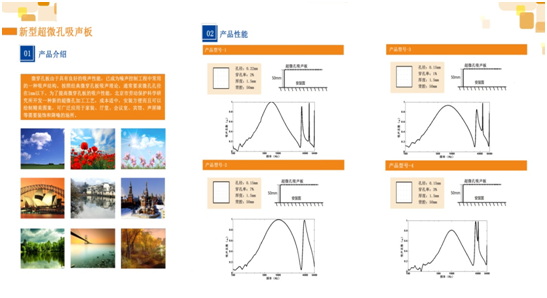

Novel Ultra-Micro Porous Acoustic Panel Absorber

Soft Film Ceiling Sound Absorber